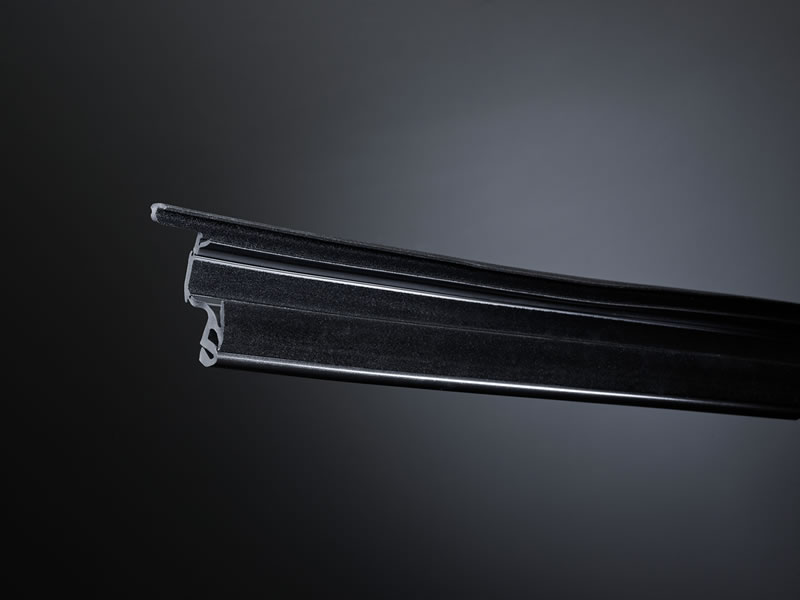

z-pillar cutting for glass-run pillar seals without metal carrier

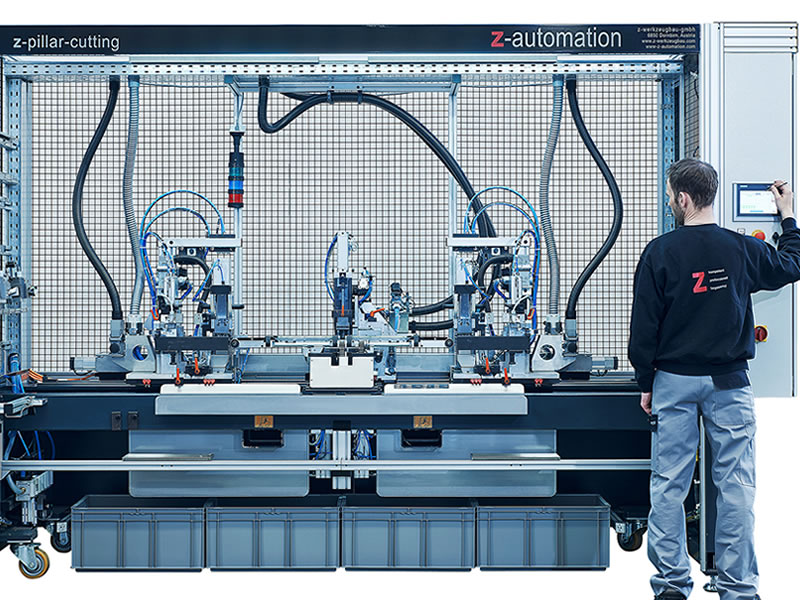

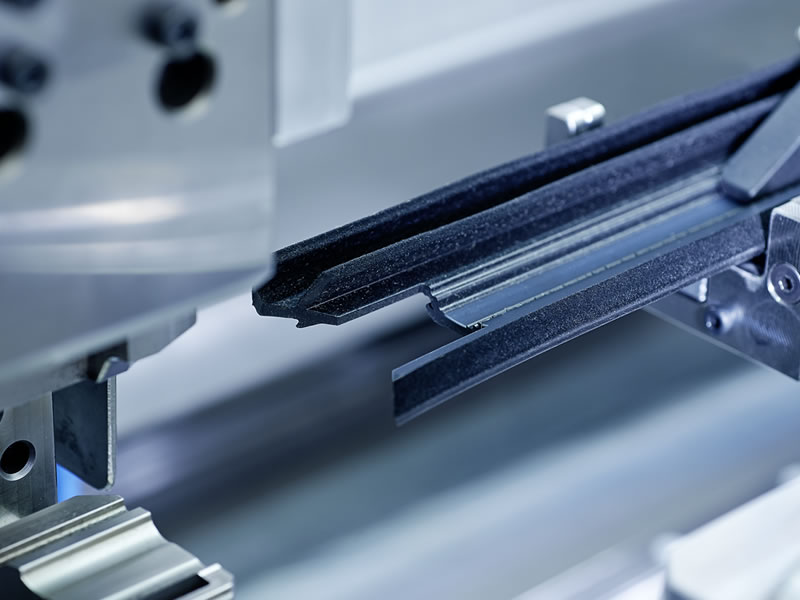

Proven production system with high process reliability for pillar seals without carrier and with tightest tolerances. During a single clamping setup, typical glass-run pillar seals are fully notched including stepped end cuts and, if required, longitudinal cuts, window notching, etc.

A universal system which can be equipped with product-specific tool sets: Thanks to our quick-tool-change interface, the system can be easily set up to process different profile cross sections and products within a few minutes.

Double raw length profiles are processed into left and right parts to ensure an efficient extrusion or raw cut process. Of course, the option to produce only left or right parts can be selected at the operator panel.

Sophisticated profile cross sections

Our experienced engineers develop product-specific holding fixtures, feeding systems and tools which ensure outstanding results and low scrap rates.

Optimized system operation

An ergonomic operator station is a must. We have created a smooth workflow thanks to a system which unloads the processed profiles into a trough in the workroom and which is easy to manually load with raw profiles. Ideally one operator handles two systems alternately.

Typical cycle time

15 seconds process time for a product pair (left and right part) and 15 seconds for manual loading and unloading. If two systems are operated alternately, this equates to a typical overall cycle time of 15 seconds for one product pair.

Maintenance and service

To guarantee a smooth operation, z-automation relies on proven systems, the use of commonly available parts, detailed operating and maintenance manuals as well as remote maintenance via online remote control.

Find more information in our z-pillar cutting product brochure.

Your benefits

- process capability for the notching of pillar seals

- lowest possible scrap rate

- tightest tolerances and maximum optical quality

- flexible universal systems which can be set up with product-specific tool sets

How can we help you? Contact