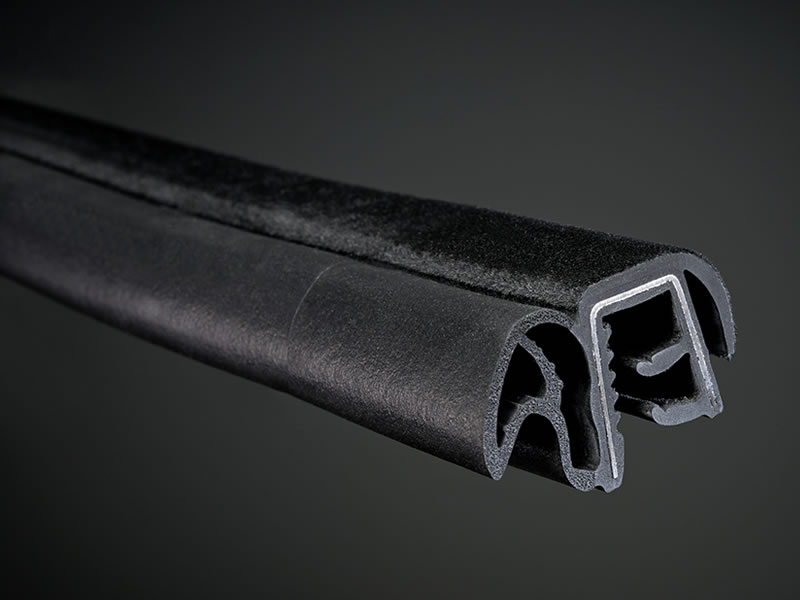

Door and trunk seals

Profiles for door seals at the body or door side, as well as for trunk and engine lids must meet high functional and optical sealing requirements. Therefore, profiles are no longer just fixed to the vehicle - the ends of profiles are spliced beforehand to create a sealing ring. It is crucial for the splice to be stable and visually appealing.

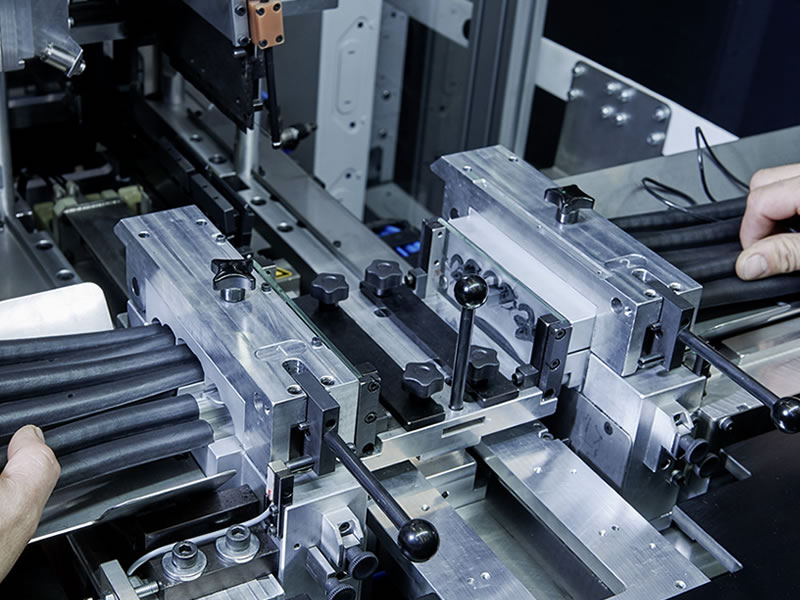

Splicing systems for sealing profile rings

z-automation splicing systems joins your sealing rings with consistently high quality and

- high process capability with minimum scrap rate due to automated processes

- independence from the extrusion end cut due to the integrated face-grinding process

- no manual readjustment of the heating process

- ergonomic and practical processes for the operator: ideally one operator is responsible for two systems

- integrated hole punching of the splicing foil for improved water and air management in tube areas

- the ability of processing most profiles with butyl

z-automation offers two universal and flexible solutions: z-inline-splicing for the highest degree of automation, the highest output and direct coupling to the extrusion line or z-splicing stand alone for a decoupled splicing process with a lower degree of automation.

Both solutions use the same basic technologies for the processing of profile ends and for splicing. The loading of raw profiles, removal of foil rests, unloading of sealing rings and cycle time depend on the chosen solution.

Your benefits

- a splicing system ideal for metal carrier profiles and complex profile cross sections

- splices with maximum optical and technical quality

- process capability for PE-splicing

- sustainable investment: a flexible universal system that can be equipped with product specific tool sets

- ergonomic operation, simple maintenance and service

- customer service: within just three weeks we will provide you with parts produced on our machines using prototype tools developed especially for you

Find out more about z-automation products for the sealing ring production: z-splicing

How can we help you? Contact