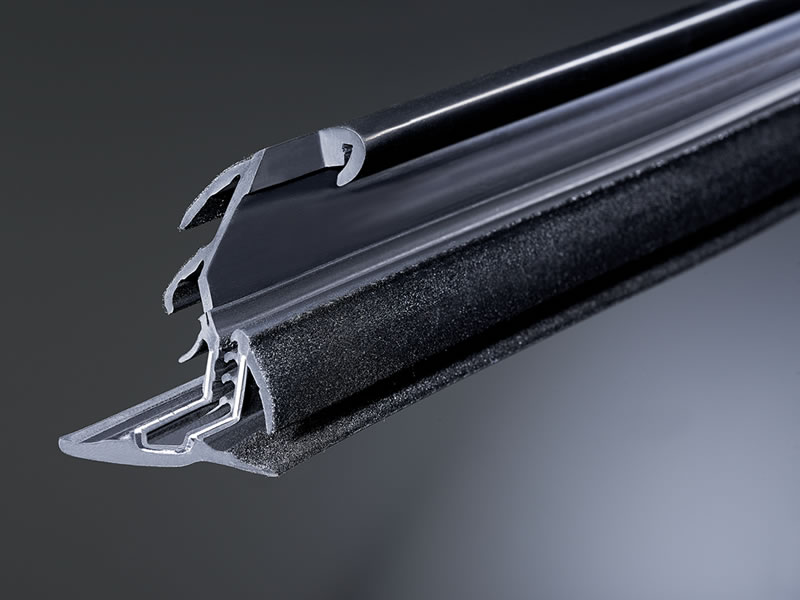

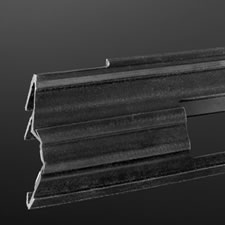

Window seals

Window seals face high functional requirements: they have to compensate for body and glass tolerances and play an important part in the overall appearance of the vehicle.

Inner and outer waist belt seals, glass-run header seals

Carrier profiles made of EPDM, TPE or composite materials.

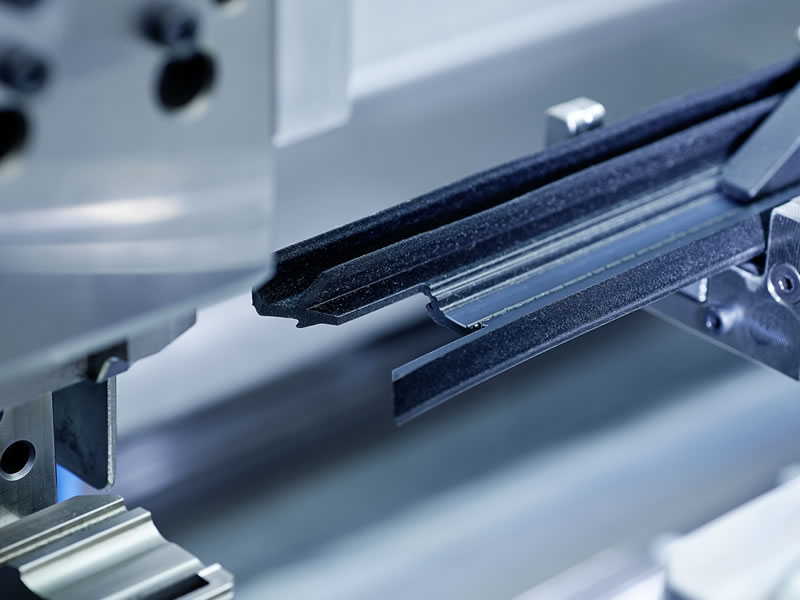

Key features include tight dimensional tolerances, proven capability, high processing quality for cutting, bending, integrated injection moulding of TPE end caps or moulded parts, as well as tool technology with automatic or manual compensation for black and bright profiles. z-automation is your partner for such requirements and offers two solutions: z-transfer and z-sequential cutting.

For the production of large quantities we recommend our universal automated system z-transfer, while z-sequential cutting is ideal for smaller or medium batches. Both systems can be equipped with product-specific tool sets, which are easily exchangeable via our standardized quick change interface.

Glass-run pillar seals

Profiles without carrier, made of EPDM, TPE or composite materials.

Double raw length profiles are processed into left and right parts in an automated process during which the product stays clamped in place the whole time. For this purpose, we provide you the universal z-pillar cutting solution that includes product-specific tool sets, which are easily exchangeable via our standardized quick change interface.

Your benefits

- process capability ensured through integrated, fully automated processes

- tightest product tolerances

- the product stays clamped in place during the whole processing

- proof of quality including capability analysis carried out with our own optical measuring system z-md2000

- universal production lines with standardized quick tool change interfaces

As your supplier of production lines we will ask you how many vehicle sets you need to produce per year. Based on this information, we will use our tool to develop the most cost-effective solution for your company, taking into account the degree of automation, number of employees required and cycle time, while always taking the necessary investment and running costs into consideration.

If you already own a z-automation line for a product which will soon be phased out, all you need for your new product series is a new tool set, instead of a whole new line. This flexibility makes your z-automation system a highly sustainable investment.

How can we help you? Contact

Find out more about z-automation products for the window seal production:

z-transfer

z-sequential cutting

z-pillar cutting

z-measuring device